Don’t you hate it when you finally find your ideal set of aftermarket alloy wheels, only to learn that, for whatever reason, they won’t fit your car? There’s little more annoying to your average petrolhead than a duff offset, a decidedly awkward PCD selection or a centre bore that’s miles off. It can really take the shine off shopping for new wheels, an experience which really should be one of the highlights of modified car ownership.

If the above sounds familiar then we have some good news for you, the Wolfrace Complete Fitment Coverage (CFC) programme is now larger and more inclusive than ever before, meaning that there’s a very, very good chance that you’ll be able to run your dream Wolfrace wheels – no matter what you drive!

While far from a new service, the Wolfrace Complete Fitment gonfiabili Coverage programme has recently expanded, meaning that there’s now a greater chance than ever before for key wheels within the range to be made to fit all manner of makes and models. Need some Wolfrace Classics for your Lancia Delta? No problem. A set of Pro-Lites for your Citroen AX track car? The work of moments! It’s all part of our commitment to ensuring our customers can buy in complete confidence, safe in the knowledge that their dream wheels will bolt right up to their hubs with the minimum of fuss.

Our CNC machines aren’t merely state of the art, they’re super fast – and we have 3 of them!

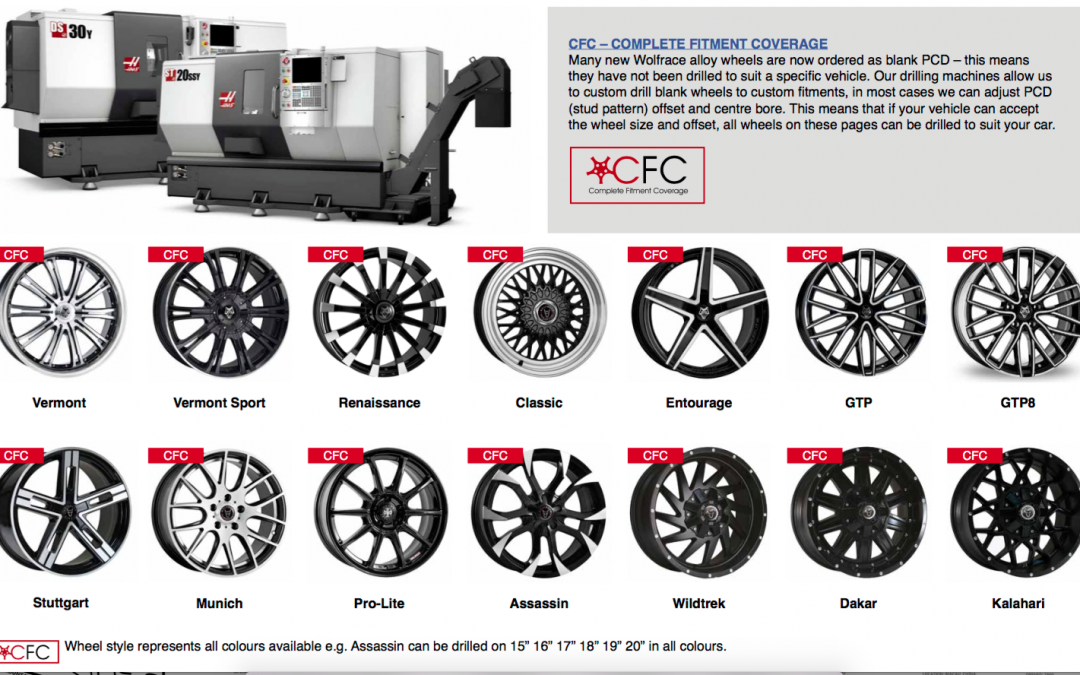

The CFC programme is only possible thanks to our decision to invest in a trio of Computer Numerical Control (CFC) drilling machines some years ago, and these have given us capabilities many wheel makers can only dream of. They allow us to perform all manner of advanced modification work to a huge number of our alloys, including adjusting parameters via custom offset machining, PCD drilling, centre bore adjustments and bespoke drilling, and spigot ring location, all using brand new, blank Wolfrace wheels. The CNC machines are nothing if not accurate, able to efficiently drill PCDs to a fraction of a millimetre in minutes. Each alloy is then extensively tested and inspected, while all stud hole de-burring is carried out by our skilled engineering team by hand, a process which ensures a perfect finish.

The Classic is just one of the wheels covered by our CFC programme

Our CNC machines can carry out a variety of tasks at the same time, while 4, 5 and 6 stud PCDs can be simply and swiftly drilled in moments, ensuring that using our CFC programme doesn’t involve waiting weeks for your alloys! Indeed, the high speed nature of the machines means that, in most cases, the whole process adds a mere 48 hours to the order turnaround time. Lastly, the sheer size of the machines means that they can handle almost any size of wheel, meaning those seeking 15in Pro-Lites are just as well covered as those ordering 20in GTPs.

The full list of wheels included in the CFC programme can be found below, but even a brief glance at the wheels in question is enough to underline just how varied the Wolfrace range is, and also how capable the CNC machines can be! Big, imposing designs like the Wolf Design GTP and Entourage share space with more mainstream offerings, the Classic, Assassin and Pro-Lite being but three examples. You can even have all wheels within the Explorer line (Wildtrek, Dakar and Kalahari) re-worked to suit you specific requirements, so great news for off-road fans!

So there you have it, the lowdown on our Custom Fitment Coverage programme, the best (and easiest) wat of getting Wolfrace wheels to fit your car!

Wheels included within Wolfrace CFC programme:

Vermont Vermont Sport Renaissance

GTP Assassin Stuttgart

Munich Wildtrek Dakar

GTP8 Entourage Pro-Lite

Entourage Classic Kalahari

Click through to find out more.